Capacitive Sensors: Non-Contact Detection for Modern Industrial Applications

Factories and warehouses worldwide now rely on sensors that work fast and stay dependable, even in tough settings. Because of this shift, capacitive sensors have moved to center stage, allowing businesses to check the presence or absence of objects without ever touching them. For B2B clients who want smoother automation lines, less costly downtime, and consistent product quality, getting to know this technology is no longer optional.

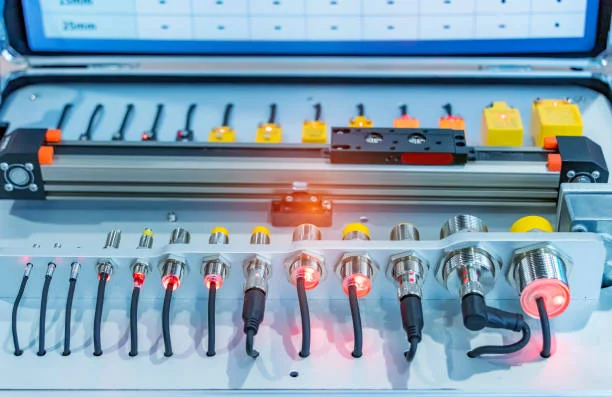

These sensors pick up tiny changes in capacitance whenever an object, solid or liquid, enters their detection zone. Unlike their inductive cousins, which respond only to metal, capacitive units can spot plastic, glass, wood, and even liquids such as oil or water. This broad material range lets engineers place them in almost any process, from conveyor systems and packaging lines to food-fill stations and robotic arms.

In the sections that follow, we break down how capacitive sensors actually work, where they shine on the production floor, how to choose the right model, and what benefits they deliver once installed. As a practical starting point, look at OMCH‘s https://www.omchsmps.com/ru/path/proximity-switch/ built for modern automation systems.

Understanding the Working Principle of Capacitive Sensors

Capacitive sensors work by measuring tiny changes in electrical storage, or capacitance. Inside the unit sit two metal plates separated by air or plastic, forming an invisible electric field. When an object with any insulating quality crosses this field, it shifts the stored charge and the capacitance goes up or down. The sensor notices this shift and turns it into a clear electrical signal that can shut off a machine or light a LED.

Because they respond to almost anything that sits between the plates, capacitive sensors can easily spot:

- Solids like wood, plastic, glass, or metal

- Liquids such as water, oil, glue, or chemicals

- Powders and fine granules

Depending on its setup, a sensor can sit flush with a wall or stick out slightly, and it can sense through any non-metal box, so factories avoid touching the material while still watching levels in tanks or silos.

Key Applications in Industrial Automation

Capacitive sensors are popular in factory settings because they detect objects without touching them. This touch-free method boosts speed and keeps workers safe, so the sensors are now used in many B2-B industries. Here are a few of the main sectors and how they profit from the technology.

Packaging and Material Handling

On a busy packaging line, capacitive sensors check whether cartons, plastic trays, or any non-metal part is present and in the right place. They also measure stack height or count layers without pushing or pulling. By spotting different shapes from a short distance, the sensors keep the line moving and cut jams.

Food and Beverage Processing

Sensors sit above silos and tanks to see how much liquid or material is left inside, letting workers refill before a shortage stops production. Because the sensors never touch the goods, they meet sanitation rules and slash the chance of spills or germs. They even read levels through glass and tough plastic, so factories dodge sensor breakage.

Pharmaceutical and Chemical Industries

In clean-room areas, capacitive sensors watch liquid heights in mixing vats, track bottles and vials as they move, and check whether caps have snapped shut. Workers stay clear of harsh smell, and the sealed set-up stops floods or leaks. That mix of safety and reliability is why labs and chemical plants trust this technology every day.

Robotics and Automated Assembly

In modern robots and automated grippers, capacitive sensors provide the silky smart touch needed for flawless pick-and-place tasks. Because they see beyond metal, they calmly signal whenever a fragile plastic part lands, stays, or tips.

Electronics and Semiconductor Manufacturing

Capacitive sensors shine in clean rooms. There, their fragile-reading skill confirms that every printed circuit board, silicon wafer, or tiny microchip is exactly where it should be. They can even whisper the exact thickness of a layer-dotted board before the next tiny process step.

Read Also: How Supply Quality NPE Surge Protective Device Supports Consistent Electrical Performance

Selection Criteria for Capacitive Sensors

Selecting the best sensor starts with asking the right questions, so the sensor works quietly in the background for years to come.

Sensing Range

Capacitive eyes come with sensing zones from a few millimeters to several handy centimeters. Tight spaces call for short range, while larger parts that glide past may need more distance.

Object Material and Size

Every material talks to a sensor in its own dialect, depending on its dielectric value. Glass or water shows up easily, but wood, rubber, or even thin film may need careful calibration. The parts height, width, and thickness also nudge how well a sensor performs.

Mounting Type

Flush sensors tuck neatly into a panel, almost vanishing; non-flush units need space around the lens so they stay clear. The factory’s true environment-mostly dust, moisture, or accidental bangs-will often choose between the two.

Environmental Conditions

Before picking a sensor, think about where it will go. Will it face water, dust, chemicals, or extreme heat? If the answer is yes, look for models with high IP ratings, like IP67 or IP68, so they stay reliable in tough spots.

Output Type and Interface

Capacitive sensors come in several output styles—PNP, NPN, analog, or digital. Match that output to your control panel, whether it’s a PLC, relay, or IO-Link, to avoid headaches down the road.

To make things easier, OMCH posts clear datasheets and specs for every sensor, giving engineers and purchasing teams the info they need to buy smart. Their proximity switch guide shows capacitive models that fit dozens of jobs.

Integration Benefits for B2B Automation Systems

Drop a capacitive sensor into an industrial line and you get real, measurable gains:

Non-Invasive Monitoring

Because they use an electric field, these sensors can “see” through glass, plastic, or thin metal walls. That lets you monitor sealed, hygienic, or explosion-proof setups, making them a go-to for food plants or chemical labs.

Reduced Wear and Maintenance

With no moving parts and no physical contact, capacitive sensors hardly wear out. They demand little upkeep and usually last years longer than mechanical switches, saving both time and money.

High Sensitivity and Customization

Many new models let you teach them what to look for, so you can set the sensitivity on the fly. That cuts false alarms and boosts accuracy, giving operators the confidence to keep the line running smoothly.

Real-Time Feedback and Control

Capacitive sensors deliver quick and steady signals to control systems, so factory automation runs smoother and managers get faster, more accurate data when decisions matter most.

Cost Efficiency

By standing in for several mechanical or inductive sensors, a single configurable capacitive unit cuts back on wires, speeds up installation, and lightens the parts cupboard for every engineering team.

As B2B sectors race toward smarter factories, partnering with sensor makers known for solid quality and tailored solutions gives companies a clear edge. OMCH backs that promise with rugged design and quick-response engineering, letting manufacturers scale with confidence.

Conclusion

From food processing to electronics assembly, capacitive sensors provide versatile, touch-free detection of objects and liquids. Their knack for spotting many materials makes them a must-have where hygiene, accuracy, and uptime cannot be traded away.

Companies thinking about new sensors or upgrading existing systems should learn how capacitive models work and how to set them up; that knowledge often unlocks big gains in speed and waste reduction. Leading brands like OMCH keep pushing the envelope, offering tough, high-performing sensors fine-tuned for today’s fully connected automation floors.